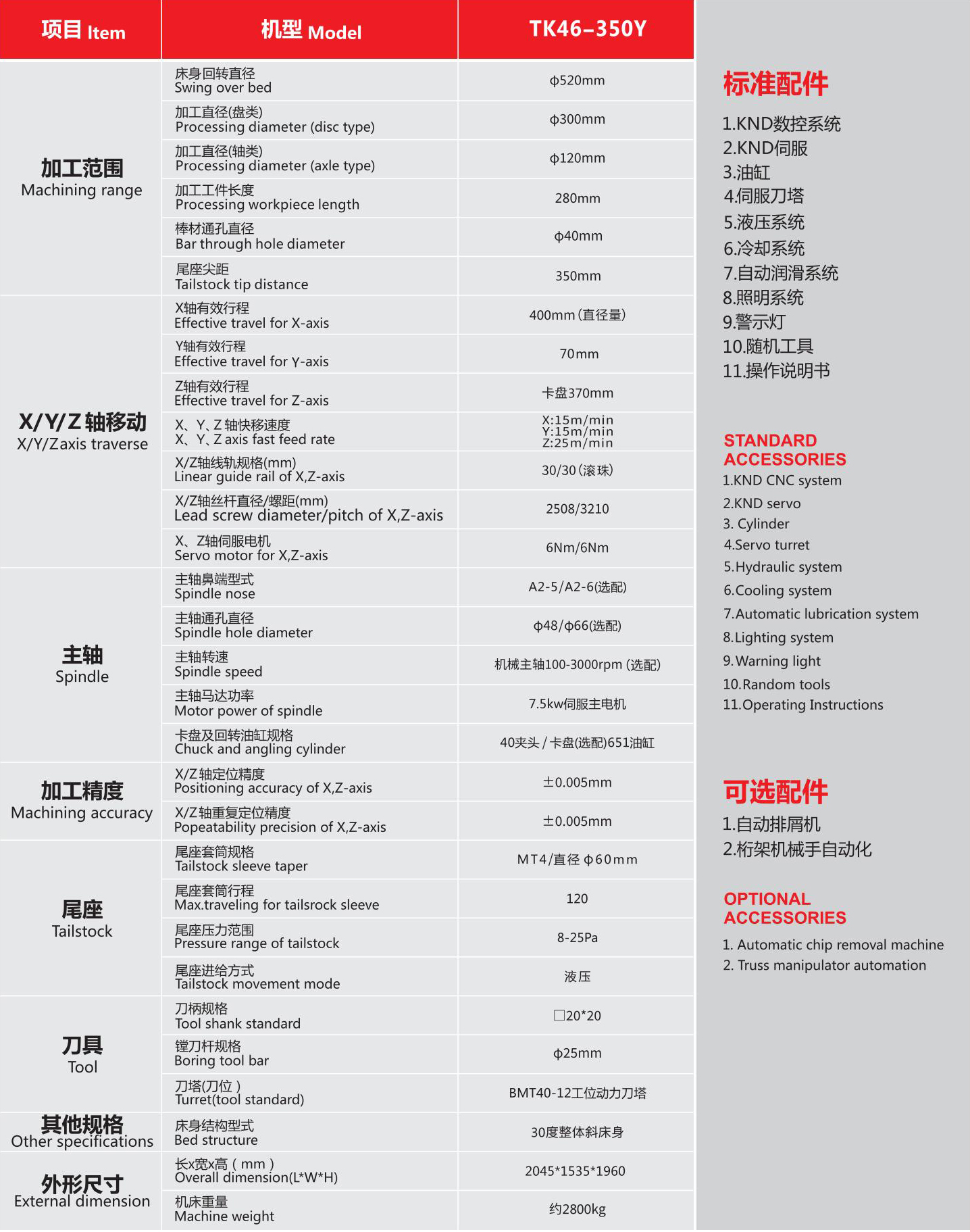

TK46-350Y Slant rail CNC lathe

- Tel:+86-576-87213806

- Email:[email protected]

1.High-precision electric spindle

This machine adoptshigh rigidity headboard. The front bearing of the main shaft is double-row cylindrical roller bearingplus thrust angularcontactball bearing, and the rear bearing also adopts double-row cylindrical roler bearing. This type of spindle bearingconfiguration makes the entire spindle group have high rigidity, which is suitable for high stifness and high precision CNClathes required;for powerful cutting.

2.Bed structure

The use of high-rigidity cast iron, resin sand process, bed feet and the overall structure of the bed with a smooth chip, compact structure, beautiful shape and so on.

3.Turret way

The novel servo turret ensures a repeated tool change error of ±3um , ensures high-speed and accurate tool change, and can significantly save processing time.

4.High precision feed

Feed the entire servo drive shaft, the drive motor and the Taiwan Syntec System, the Taiwan Yintai linear guide, ensure machinina precisiorand long time precision into the shaft to repeat positioning accuracy of <±5um.

5.Efficient processing

The X axis can move up to 15m/min, the Z axis can move up to 25m/minute, high-precision hydraulic rotary cylinder,precision Taiwan thousand island chuck. Increased toughness material cutting and strengeh Ability to cut.

6.Strong cooling

High-power strong cooling pump, improved parts cutting, according to customer reguirements can be installed 1-4 cooling tube, cooling performance.