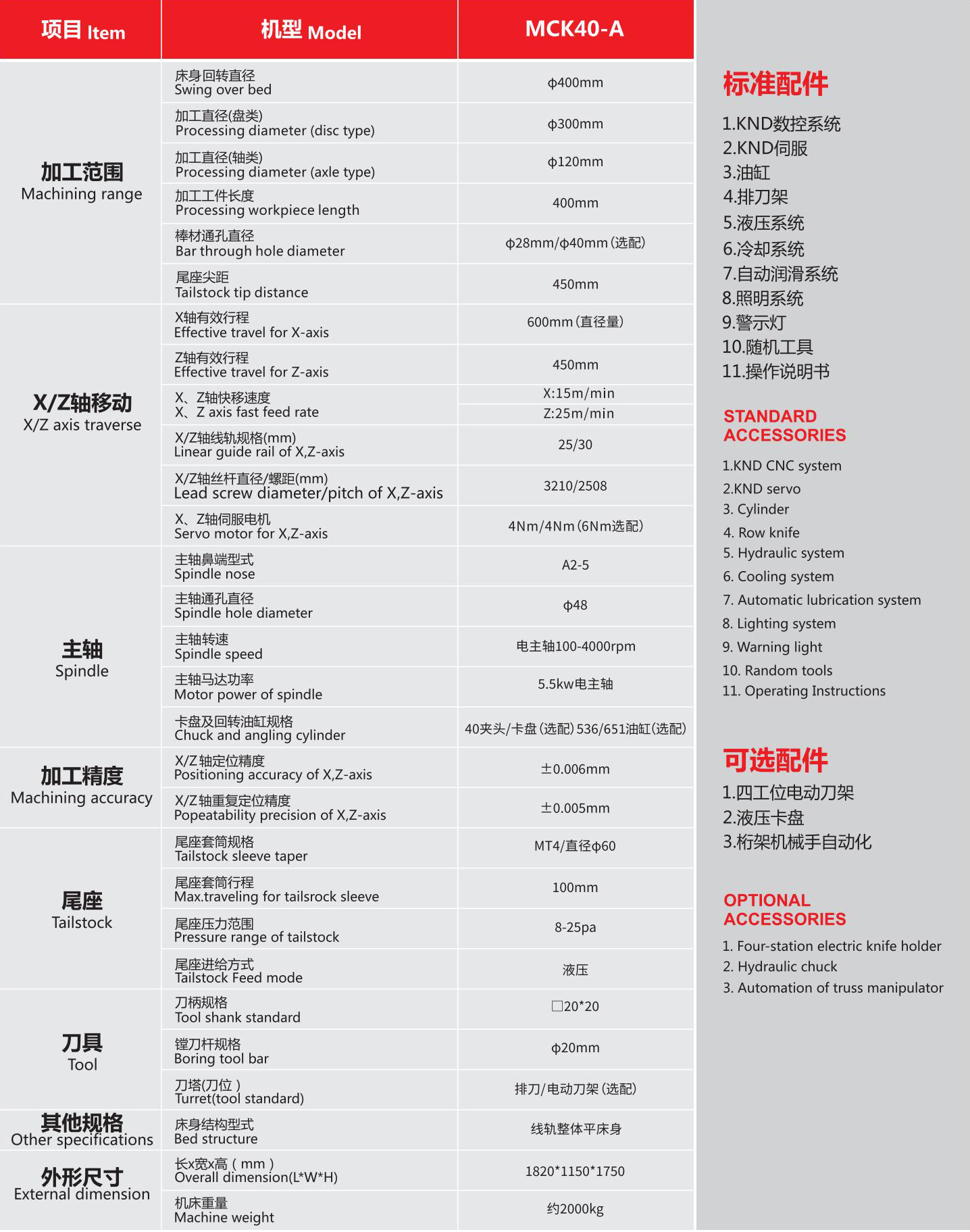

MCK40-A Line CNC lathe

- Tel:+86-576-87213806

- Email:[email protected]

1.High-precision electric spindle

The machine adopts motorized spindle head, the traditional belt driving technology is removed, the bearing adopts high speed before and afterpairing, it has high speed, high rigidity and low noise. Durable precision, spindle runout<3um.

2.Bed structure

The use of high-rigidity cast iron, resin sand process, bed feet and the overall structure of the bed with a smooth chip, compact structure, beautifulshape and so on.

3.Knife cutter

The novel servo turret ensures a repeated tool change error of±3um , ensures high-speed and accurate tool changeand can significantly save processing time.

4.High precision feed

feed the axis ofthe whole servo drive, the use of Taiwanintime linear quide to ensure the accuracy of processing and long time to maintainthe accuracy ofthe feed axis repeat positioning accuracy<±3um.

5.Efficient processing

FThe maximum speed ofthe machine spindle is 3000 rpm, the X axis can move up to 10 m/min, the Z axis can move up to 15 m/min, he highprecision hydraulic rotary cylinder, the precision elasticity chuck. lmprove the toughness of the material cutting and strong cutting capacity.

6.Strong cooling

High-power strong cooling pump, improved parts cutting, according to customer requirements can be installed 1-4 cooling tube, cooling performance.